DTF water-based inks revolutionize textile printing with vibrant colors, durability, and environmental friendliness. Common print issues include uneven distribution, blotchy prints, and misalignment, caused by incorrect settings, substrate preparation, or hardware problems. Troubleshooting involves checking ink viscosity, temperature, plate cleanliness, and fabric/ink preparation. Regular printer calibration and maintenance are crucial for high-quality custom sheet printing using DTF water-based inks.

Are you experiencing print quality issues with DTF (Direct-To-Fabric) water-based inks? This comprehensive guide is your go-to resource. We’ll demystify DTF ink basics and equip you to identify and troubleshoot common problems. From understanding ink composition to effective troubleshooting techniques, this article covers it all. By the end, you’ll be confident in ensuring consistent, high-quality prints with your DTF water-based inks.

- Understanding DTF Water Based Ink Basics

- Identifying Common Print Quality Issues

- Troubleshooting and Resolving Common Problems

Understanding DTF Water Based Ink Basics

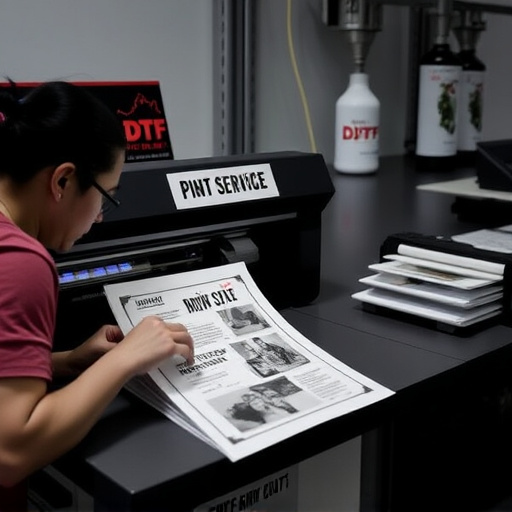

DTF (Direct to Fabric) water-based inks are a game-changer in the world of textile printing, offering vibrant and durable color for various fabrics, especially in bulk DTF shirt production. These inks are designed to adhere directly to fabric fibers, ensuring high-quality prints on t-shirts and other garments. The ‘water-based’ part refers to their composition, which includes water as a primary solvent, making them environmentally friendly compared to traditional solvent-based inks. This simplicity also makes DTF printing for t-shirts accessible to both professionals and hobbyists alike.

Understanding the basic properties of DTF water-based inks is crucial when troubleshooting issues. These inks are known for their quick drying time and ability to withstand washing without fading, making them ideal for fast production runs. They are suitable for a range of fabrics, particularly cotton and poly-cotton blends. When used correctly, DTF prints can achieve a soft, fabric-like hand feel, ensuring customer satisfaction in the final product.

Identifying Common Print Quality Issues

When troubleshooting issues with DTF (Direct to Fabric) water-based inks, understanding common print quality problems is a significant first step. Many issues manifest as defects on the final printed product, such as uneven ink distribution, blotchy or patchy prints, and misaligned designs. These challenges often arise from improper ink settings, poor substrate preparation, or hardware malfunction. For instance, incorrect ink flow rates or pressure can lead to inconsistent printing, while a subpar fabric surface may cause ink bleeding or skipping.

Identifying the root cause becomes crucial in resolving these issues. Check for ink settings that might be too light or heavy, ensuring optimal print density. Verify substrate cleanliness and smoothness to prevent any interference with ink adhesion. Regularly calibrate and maintain your DTF printer to keep it in top condition. For DTF printing, especially on apparel like t-shirts, proper preparation of both the fabric and ink is essential for achieving high-quality results.

Troubleshooting and Resolving Common Problems

When troubleshooting issues with DTF Water-Based Inks, start by considering basic factors like ink viscosity and temperature settings. Ensure your direct to film printer is calibrated correctly, as improper settings can cause ink clumping or spreading, affecting print quality. Regularly clean the printing plate and ensure it’s free from any residual ink buildup, which could lead to smudging or uneven transfers.

For optimal results with custom sheets for heat pressing designs onto garments using DTF transfer techniques, maintain consistent humidity levels during the printing process. High humidity can cause ink bleeding or drying issues, while low humidity might result in a brittle finish. Additionally, inspect the quality of your design files; pixelation or poor resolution can negatively impact print clarity. Regularly calibrate and maintain your equipment to address common problems effectively.

When troubleshooting issues with DTF water-based inks, understanding the fundamentals of these inks and identifying common print quality problems are key. By familiarizing yourself with the basics and following the provided troubleshooting steps, you’ll be well-equipped to resolve a wide range of challenges. Remember that consistent results rely on meticulous care and attention to detail. Continue to experiment, learn from each attempt, and soon you’ll master the art of creating vibrant, high-quality designs using DTF water-based inks.